- -------PRE

ENGINEERING CONCEPTUAL DESIGN AND PROMOTION SERVICES--------

|

-

-

| CUSTOM DESIGNS - DIRECT CONTRACT SERVICES |

-

|

GA

Plans - Alaska State Police Patrol Vessel GA

Plans - Alaska State Police Patrol Vessel

In 1998 we might not have coined the phrase

"From Concept to Reality" but I sure lead the saying

ahead of a lot of other folks. In 2002 just before leaving for

a photo/video documentary acquisition in Mexico Chris Kennedy

was tending a proposal for the State of Alaska. He asked me to

rework a vessel design we had jointly developed and convert the

GA plans into a patrol boat. Based on my experience in the Coast

Guard I fashioned a number of features I would like to have seen

on our cutters. For example, a mess deck on the main deck where

you exited ready to tend the lines. After all, the mess deck

is also the coffee bar aboard any boat so why put it below deck.

Another is using the stylish webbing on

the side of the vessel as the vent chambers to exhaust heat out

of the engine room allowing it to warm the upper deck reducing

dangerous icing which contributes to instability as the center

of gravity is raised by the weight of frozen seawater on the

superstructure. A real problem while underway in Alaska during

the winter.

After developing the deck plans and GA

drawings I digitally painted a rendering and assembled a video

to market the design to the Alaska State Troopers. The result

of our efforts is the P/V Enforcer which is still underway serving

Ketchikan, Alaska.

|

-

- The design work for this 82' vessel started

out based on a 52 page specification book from the State of Alaska.

The criteria developed for this vessel was the work of dozens

of troopers providing input as to what they felt the boat should

be able to accomplish on a mission. Added to that, Chris Kennedy

and Rob Watson put their own special touches to the job at hand

based on experience and practical common sense. Click the image

(right) to see more.

|

|

|

PowerPoint for Installation of Escalators

For Review and Action - Selecting this

icon will lead you to use your default process or application.

If you do not have Microsoft Power Point or compatible you can

go to Microsoft to download it here.

|

-

|

LASER SCANNING FOR SPONSON ADDON

You can see how rough the side of this

OSV is after years of abuse. When it came time to add sponsons

for an upgrade the concern was the it would be in drydock for

less than a month, return to sea, and them be back in 1 year

for the add-ons. During that time the engineer was to develop

the fit-up lines. I was commissioned to bring in a laser scanning

crew to the yard and arrange for the scan which would result

in a 3D CAD line drawing for the enginner to construct the sponsons

from.

|

-

|

- 3D CAD FROM A 2D PROGRAM - YES IT CAN

- Quiet the argument that AutoCAD 2D can

not be used to create a 3D object. In the context of 3D I will

agree that AutoCAD is not a full 3D program. However, it can

generate 3D CAD as long as the objects do not use something like

a B-Spline Progressive Sweep. In other words, start as a small

radi and advance to a larger radi as it sweeps back over itself.

I think the best way to solve this is say that if it requires

a CNC machine to build it because it can not be made in a standard

mill, you can not build it accurately in AutoCAD.

|

-

Whether

it's 2D or 3D design or digital painting or video animations,

we've proven over and again to be a valuable asset to individual

clients who haven't quite decided what they want and for those

who are not ready to dive into the engineering of their project. Whether

it's 2D or 3D design or digital painting or video animations,

we've proven over and again to be a valuable asset to individual

clients who haven't quite decided what they want and for those

who are not ready to dive into the engineering of their project.

-

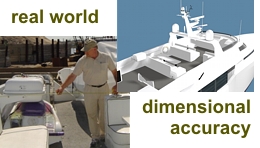

- One important aspect of MarineImaging

is about being able to take a shortcut through the "study

plan" stage by constructing dimensionally accurate parts

and lofting them into an assembly to help clients visualize the

end result. To achieve our goals we offer

|

- OVERALL FLEXIBILITY

- FAST TURNAROUND

- PROPRIETARY AGREEMENTS

- DIMENSIONAL ACCURACY

|

- NATIVE AUTOCAD PRODUCTS

- REALISTIC VIEWS

- SITE SPECIFIC REPRESENTATION

- MULTIPLE OUTPUT OPTIONS

|

|

HIGH END HAIR SALON

These photos do not even do justice to

the hair salon fixtures and interior of the salon. Designed by

my daughter and 3D modeled and AutoCAD design by myself we put

together a 12 station styling center, Color Bar, Shampoo and

Pedicure, and a reception desk that could allow 4 people to work

uncrowded. All made with carbon and stainless steel and designed

so that only two people were needed to carry and assemble every

piece.

|

|

|

BAYCRAFT WHALE WATHCER CONVERSION

This 98ft Breaux Brothers Baycraft was

one of the first fast aluminum crew boats in the Gulf and one

of the best in its day. It was purchased by a private individual

and brought to Galveston for refitting. I was commissioned to

draft a new look in AutoCAD working with the owner. First, I

had to crawl from stem to stern and measure every detail because

there were not any drawings available. Another note was that

I included engine room exhausts into the webbing on the side

uprights. You can see the vents in this image. The swim platform

added room for 450 gallons of fuel ballast and the new engines

were expected to push the boat along on a 18 knot plane at cruise.

The reason it is being lifted is due to having been beached and

thrown over on its side during the hurricane.

|

-

-

|

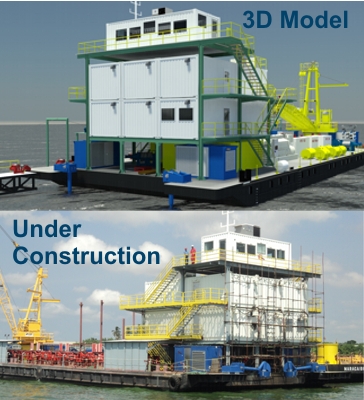

LAKE MARACAIBO, VENEZULA ACCOMMODATION

BARGE

During my employment with Thrustmaster

of Texas, Inc. in Houston I had the opportunity to work on some

very fast turnaround models in 3D MAX. Again emphasizing that

nearly ever model I develop comes from some form of AutoCAD drawing

or actual measurements I took.

This particular project is the best example

of developing a 3D model from 2D AutoCAD drawings. The actual

vessel, under construction and shown in this photo, was NOT even

a real barge when I made the 3D model. In fact, the 3D model

was used on brochures to promote the barge to Venezuela interests,

and then the barge was built using my models and their drawings

as the references.

The photo (left) was taken during construction.

As the model was developed place holders were used until the

actual product could be modeled. Mind you, I am developing this

model AND working on tradeshows and brochures all at the same

time.

|

-

|

VESSEL SCENE COMPOSITIONS

What is wrong with this picture? The 3D

model of the ship is actually 350 feet long in the scene, which

is correct. The problem is one of the inherent problems with

3D modeling. To be so focused on the object that we forget the

lighting. We have a beautiful moon in the background, reflection

off the water is near perfect. The problem is illumination of

the tanker. The light cast onto the tanker from this side would

have to be huge to cover that much area. Much larger than reality

can allow. And as a result the tanker appears to be false because

it would have to be much smaller to be lit so.

|

-

|

SHADOW STUDY

One thing I like so much about 3D Max is

that you can position your model and then set a day, date, and

time in order to see where the shadows will fall. In this case

the vessel was oriented by a compass rose to match the position

when moored at the owners dock. The time was set for the afternoon

at about 2:00 and rendered. Here you can see where the shadows

would be on the upper deck, and on the solar panels over head

of the open cockpit.

|

-

|

SPECIAL PURPOSE VESSELS

A river ferry in the Middle East has to

operate in severe flood and drought conditions, and especially

with heavy debris in the water. The premise behind my investment

in this design is not the ferry as much as it is the the hydraulic

lift thrusters which can be lifted to run with a more shallow

draft, tilted up to land on shore. The hydraulic podded motor

is less subject to damaging the prop if debris is ingested into

the nozzle. In this particular application the engines would

be water cooled and below deck leaving the upper deck for vehicles,

emergency gear, and passenger cabin space. In others, the engines

can be placed on deck and hydraulic lines ran to and from the

HPU power packs.

|

-

|

BARGE WITH PROPULSION HAVING LIFT OPTIONS

Developed to carry cargo containers in

double stack this barge would need to enter shallow waterways.

The OD thruster with lift was the perfect solution.

|

-

|

TACTICAL TRANSPORTER (TTS)

Developed to carry cargo containers up

the Tigress and Euphrates rivers to avoid dangerous roadways

the Tactial Transporter is SYSTEM, not a barge. Using Thrustmaster

hydraulic thrusters which can tilt and continue to operate through

shallow waters, these barges connect electronically through a

DP system. Once underway personel never need get out onto the

deck until they arrive at their destination.

|

-

|

TRANSPORT CAPABLE RV BARGE (RVB)

Talk about your ultimate PARTY BARGE! This

RV Barge Concept was run through the U.S. Patent office only

to find that there were at least 7 similar patents so the project

originator decided to abandon the idea of delivering over three

hundred units to marina operators around the U.S.. Still, the

concept holds to OUR same idea of developing the model in AutoCAD

first, then producing renderings for promotional purposes.

|

-

|

HYDRAULIC STEERING PUMP

- These steering pumps support 200hp electric

motors. While all of the details are not included on the pump

there are enough details to place the pump along side a thruster

unit to determine if it will fit into a room or on deck to serve

the steering solution.

|

|

-

|

ELECTRIC WINCH BRAKE

The electric winch brake is used in a deck

crane assembly (Examples page) to prevent free-falling cable

and hold for safety purposes. I was commissioned to create a

video of the crane which was still being prototyped. The video

was to run at the New Orleans Workboat Show. When the model was

complete I used it in a semi-transparency of the crane housing.

When I use the crane in a scene I no longer need the model and

will delete it out of the crane to require less data manipulation.

|

|

-

Devices

/ Equipment Developed by Charles R. Watson

(A few of these

I built or repaired in my home garage.)

- CMM and Mechanical Measurement

Devices

|

|

- PLC Driven Pneumatic Logic Control

Box

|

|

-

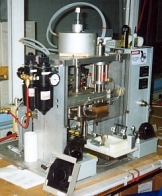

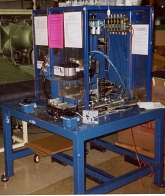

- Conversion of Discontinued CNC

Mill into CNC Heatstaking Tool For Medical Parts

|

|

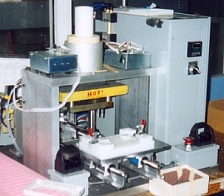

- 3 Station Pick & Place Dual

Heat Staking

- Iomega JAZ Internal

|

|

-

- Dual Position Heat Staking Single

Cycle - Digital Equipment Corporation Fan Assy.

|

|

- P/C Board Heat Stake and Testing

- Digital Equipment Corporation Bezel Assy

|

|

-

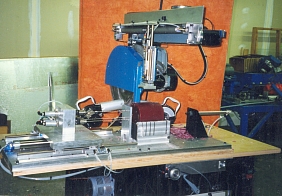

- Rotating Two Position Sonic Welding

Fixture - Digital Equipment Corporation

|

|

- Vibrator Bowl Feeder - Sonic Weld

With Light Screen - Digital Equipment Corp

|

|

-

- Kitchen Sink Former - General

Electric Plastics R&D

|

|

- Production Racks / Automatic Saw

/ Surface Ground Q/C Fixtures

|

|

-

- 4-Position Gate Clipper

- Compaq Contura Bezel

|

|

- HP 3069 PC Tester

- Prototype Pin Board Assembly Tester

|

|

-

- Heat Staking Base With Pneumatic

Logic Controls & PID Temp Controller

|

|

- Colorado Memory Systems

- Assembly Staking

|

|

-

- Automatic Saw / 3x Drill Candles

- Wicks-N-Sticks (Pneumatic Logic)

|

|

- Automatic Robotic Sprue Clippers

- Colorado Memory Systems

|

|

-

- © 1997-2016 c.r.

watson - all rights reserved

- The use of any trademarks,

trademarked names, and/or copyrighted information is stated as a fact of record and is not

- intended to imply endorsement

of any kind. The use of any pictures, writings, or materials

from this site without

- express written consent

of Charles R. Watson dba Watson Enterprises aka MarineImaging.com

is forbidden.

|

|