- -------PRE

ENGINEERING CONCEPTUAL DESIGN AND PROMOTION SERVICES--------

|

-

-

| LASER SCAN TESTING THE PROCEDURE |

-

-

|

Before scanning the Fairfield Encounter we had

to prove the concept and test out the procedure. The scanning

crew needed a bit of training as they had never scanned a boat.

We set up a catamaran near their office and highlighted the concerns

they would face on the dry dock such as limiting where they could

set up the scanner and dealing with having to reach so much area

in a small distance with the bottom possibly being obscured. |

|

-

-

| LASER SCAN TO AUTOCAD FOR SPONSON

FITTING |

-

|

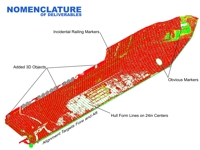

Now that we have the process down and the vessel

has arrived and loaded into the dry dock it is time to set up.

On the left the crew sets the laser scanner. On the right I have

laid out the nomenclature of a scan using the first original

scan in AutoCAD. The scanning process uses a triangulation method

to create the surface but we need to establish a fore-aft base

line and then other identifiers that would be relevant to picking

locations and to work around with the new frames. |

|

-

|

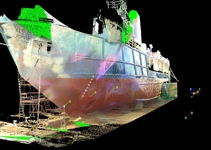

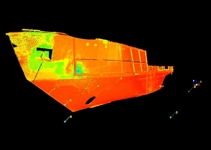

The scan produces a 3D image from the triangulated

cloud of points and applies a photo overlay (left) to identify

points of interest. In the right image you can see where plates

were welded onto the hull and even small collision dents. The

software used to interpret the data and make it work on 32bit

computers also allows measuring from point to point and mean

surface depths. |

|

-

|

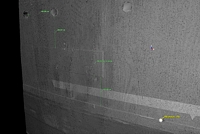

Once in the computer the operators cleaned up the

image to have only essential information the image was turned

off. Here (right) you can see the cloud data points. Where the

laser could not scan is a technical shadow. Such as the chain

in this image. The chain had been dropped in order to retrieve

and repair the anchor. In the image above left you can see the

chain hanging from the hawsepipe and the shadow behind it. During

cleanup the crew removed the chain but you can still see the

shadow. |

|

-

|

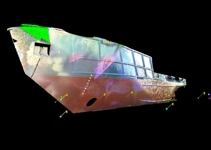

In the above images you can see reference points

on the hull. The points shown are actual balls set on the deck

so that the crew could move to the back of the vessel and scan

from that side. The two scans were merged together and the spotting

points overlaid so that they matched up That data was then taken

by me on a HD drive where I used standard AutoCAD to open it

and segregate sections so that I could trace the lines in AutoCAD

format. |

|

-

|

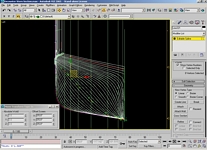

Left is a screen capture where the lines were generated

section by section. I will not reveal how I was able to layers

these lines but it was time consuming. Two weeks, 12-16 hours

a day using AutoCAD. I did not have the $14,000.00 for the software

so I had to use what I had. Patience.

Right is

the line drawing that resulted. While I had included the location

of the pipes using circles, the final decision was to leave the

pipes off and trim those in during installation. |

|

-

|

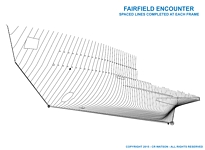

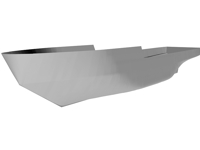

Left we have the final assembly generated

from the line drawing in Rhino 3D. The image was done to completion

and the sponsons made and installed. As simple and unimposing

as this image seems, in AutoCAD and Rhino it is to size and detail

sufficient to actually build a matching hull of a sister ship.

Thanks to Roger Fyffe, Naval Architect

who created the final image. Whereas I could generate the line

drawings in 3D my programs would not skin it as he did in Rhino.

|

|

-

- © 1997-2016

c.r. watson - all rights reserved

- The use of any trademarks,

trademarked names, and/or copyrighted information is stated as

a fact of record and is not

- intended to imply

endorsement of any kind. The use of any pictures, writings, or

materials from this site without

- express written consent

of Charles R. Watson dba Watson Enterprises aka MarineImaging.com

is forbidden.

|

|