|

1.

When I took over the project the entire 54 acre tract was wooded

pasture. Cows ran the property and the landscape ranged from

swamped gullies to woods to open pasture. The carcass of a cow

led me into an area where the long dried bones of other dead

cows was scattered throughout the thick underbrush. This property

had long been used for agriculture purposes for running cattle

and I didn't want someone to later say that we had harmed the

cows so we added fencing and even stretched barbed wire ourselves

to separate the cows from the construction site. |

|

2. During my original review of the property

I found evidence of an old telephone line. The easement only

ran a few hundred feet and then terminated near the middle of

the property. Practicing "due diligence" and just for

good laugh I called the Operator and asked for "Enterprise

9800."

We did eventually get a release of the

easement made necessary because it continually showed up on the

plats causing problems with getting later easements that were

necessary for our electrical service.

|

|

3. This is my trusty "side-kick".

This is the guy that makes sure that the people on site are doing

what they say they are. Be it at 3:00 am, on the weekend, or

until "dark-thirty", hiring Roy Weisinger was one of

the best moves we made. With over 50 years experience Roy proved

to be a major asset as contractors sought his advice and site

workers took his direction without complaint.

Here Roy has mounted a digital camera on

the end of a PVC pipe. He's set the timer on the camera to snap

after 10 seconds. Inserting the camera down into the boring holes

he took pictures of the conditions near the bottom where light

wouldn't shine so he could insure that the footer had been reamed

properly.

|

|

4. Proving that you have to keep an eye

on everybody. I had ordered all 54 acres completely cleared.

As the excavators and bulldozers were nearing the end of their

clearing stages this one tree stood out day after day. I asked

the operators why it was still there. Answer, "We didn't

want to clear it because it "spoke to us."

My answer was to ask, "When it spoke

to you, did it offer to sign the check for your services?"

Needless to say the tree was gone the next day.

|

|

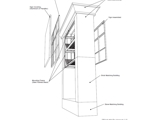

5.

The property had been surveyed a few years earlier but I considered

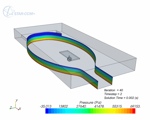

it my responsibility to know every inch of this project. Using

the survey map I walked to every marker. Once found I placed

my own marker and tape so that I would know and could be confident

in pointing out where the property lines were. This helped tremendously

as both County and State inspectors and officials came to the

site later in the project to determine our status of construction

and to fulfill their roles. |

|

6.

With the land cleared we held a ground-breaking ceremony. Not

once, but twice. The first was for county dignitaries and longstanding

customers. The sign in the background was the one at the entrance

on FM 529 announcing the project. I moved it back to the groundbreaking

and then returned it once we had completed the ceremonies. |

|

7.

The second was for the employees whom the owner attributes much

of his success. (Who wasn't in this picture? As a matter of fact,

who wasn't in almost every picture? Your truly. As usual I was

the one taking the pictures.) |

|

8.

Picking a location on the site where no buildings were slated

to be built a deep pit was dug. During the clearing process trees

and brush were piled for several weeks to dry out. Under authority

of a county permit the brush was burned in the pit under controlled

conditions. The fire pit, becuase of its proximity to the water

table, can not include anything but natural shrubs, trees, and

brush. No chemicals, no man-made matter, no cattle remains. Nothing

that seepage could take down the remaining few feet to contaminate

the water. With the property finally

clean the back-hoe operator covers the fire pit and packs it

down until there is no evidence it was every there. |

|

9.

Here the property is finally cleared and ready to begin construction.

During the process of clearing and making the ground ready there

were many meetings and details to attend. Working with the Civil

Engineers, Architects, banking officers, nearby property owners,

and MUD (Municipal Utility District) officers were just a few.

There are some environmental concerns I can not disclose on this

project. Nothing major but still affecting the schedule. |

|

10. There were quite a few times that someone

at the old office would comment that nothing was going on at

the new site. A LOT was going on, they just couldn't see it.

After all permits and plans have been satisfied

with the county the laying of storm sewer is usually a hidden

process. I say "hidden" because folks passing by the

site on the highway don't see the workers. They are down in the

holes digging trenches and laying the lines and tanks.

|

|

11.

As a fisherman I say, "Pollute it now..., eat it later."

This was just the first of half a dozen truckloads of underground

conduit and junction boxes that are typically buried under parking

lots or buildings. A site that was once capable of absorbing

rainwater now has to shed that water and do it so that it does

not create flooding conditions elsewhere around the property.

The amount of water has to be calculated and then diverted to

receiving areas of run off. Typically ditches or other forms

of drainage systems that are all part of the regional flood control

program. During and after installation the project is monitored

by county officials to insure that the plans are followed to

a T. |

|

12.

Furthering that thought we don't typically consider that the

parking lot has to be designed so that run off is at a controlled

rate. Based on the amount of water, planning for a rain event

starts at where the water enters the highest drain. From there

the remaining components must be positioned so that the last

place the water leaves at the last drain is at or lower than

where it started from. Otherwise, water backs up into the drain

causing stagnation and foul smells to constantly waft from the

holes. |

|

13.

Because this factory building and office is so large each column

requires a pier with footer. These holes and the concrete are

typically drilled down to "load bearing" surfaces.

Sometimes it is rock. Other times (as in our case) it is packed

clay down between 10 - 14 feet. |

|

14. To make the process more efficient

three crews work together. Referring to the plans the drilling

crew first digs the hole using an auger. They then move to the

next hole while the bell crew reams the bell at the bottom of

the hole. Once that is done they move to the next hole location

and the concrete crew follows immediately behind. In this shot

the belling crew is barely clear before the concrete truck is

positioned to start pouring.

Another aspect of this level of new construction

as might be seen later is represented by this picture. Any time

you move dirt you have one of two options. (1) reuse it, or,

(2) relocate it.

|

|

15. Having preplanned the location of heavy

factory machines the workers begin digging out squares where

thicker concrete will be poured. This is a monolithic slab where

the thicker concrete sections are poured at the same time as

the floor. The thicker concrete provides much needed support

for the heavy machines that would break the standard concrete

floor. It also allows anchor bolts to be drilled and firmly seated

so that the machines do not "walk" as might be caused

by machining vibrations.

These particular monolithic pours are much

shallower and very different from the machine foundations shown

later.

|

|

16.

Once the monolithic slab holes are dug the rebar has to be specially

fitted to include the additional concrete. It appears obvious

that drilling into the concrete for the purpose of installing

anchor bolts would be hampered by all the steel. |

|

17. The general contractor decided to pour

segments lengthwise rather than across the shorter width. In

the beginning I didn't see where it made any difference so I

observed the process very closely thinking I was going to learn

something new. In the end, I still say it didn't make any difference.

So, in the terms of project management

this is one of those times when you simply don't make an issue

of it and let the GC work the way they want to.

|

|

18. It's 3:30 in the morning. As I said

previously Roy Weisinger is on scene ahead of the concrete trucks.

They are ready their pour - but, within minutes Roy has a sample

of the concrete and immediately calls a halt.

These chunks of concrete rip-rap were in

the mix. This just proves why you need someone on site, at all

times and why you take samples of EVERY load. The samples with

their pour location were retained by the contractor (for a small

fee) to be held for a specific period of time. Should we have

failures of the concrecte we could pull the sample and see the

density and fill, etc., to determine if it varied from the contract

quality.

|

|

19. In addition to the concerns of underground

runs for your own site services you have to make certain to include

those services that come from outside resources such as the Electric

Company, the Telephone Company, the Gas Company, and Water/Sewer,

etc.

Point: As the project manager you have

to make certain that YOU are aware of every service run, that

you know where they are coming from and where they are going,

and how they plan to get there. You cannot leave it to chance

nor can you leave it to them to figure out and do as they please.

|

|

20.

Part of this project included the development of Thrustmaster

Drive. First slated to be a county road along private property

with an easement that would have provided a payback, the city

and county planners both eventually got involved. What started

as a simple road to allow access with large truck traffic turned

into a major county road. In addition there was another intersecting

road that went nowhere except to split the property into two

sections. Literally, it was only planned for the future and did

nothing for the next 20 years. The owner then decided to pay

for it himself and in exchange, had the road named according

to his desire. Thrustmaster Drive. |

|

21.

Hurricane Rita heads for the Gulf Coast. Needless to say construction

is put on hold as workers from around the Houston area turn their

attention to taking care of family and homes. Our family covers

from Orange County to Harris County so regardless of where the

storm hits, we are all going to be affected. And we were. But,

thanks to the Lord that no one was hurt we all pulled through

and within a couple of weeks were back up and running full steam.

We knew in advance were we could aquire the generators we need

to keep the factory running. |

|

22.

Thrustmaster decision makers pull in a MEGA-GENERATOR and connect

up to the main power. Manufacturing keeps running for days as

this monster pumped out the kW's. Those tanks in front are diesel

fuel which was consumed at about 250 gallons per day of operation. |

|

23.

Finally, the first steel is erected! As you can see in this photo

the first column on the north-east corner goes up without much

fanfare. If you look closely you can see that there is a lot

of concrete on the ground. |

|

24.

With the foundation established the frame structure begins to

move very quickly as the frames and beams were all pre-fabricated

to fit. It is far from an erector set which has holes strategically

placed to allow for a variety of assemblies. In this case if

a set of holes are off my mere inches there is going to be trouble

down the road. Either the holes have to be fixed on site, or

the holes have to be fixed on site. In other words, when you

start assembling this kind of structure there isn't much choice. |

|

25.

Out front the factory office building continues at a much slower

pace. In part because the same workers and equipment needed for

the office are working on the factory. Part two, because the

office building is far more complex in the amount of "layers"

it will take to build it. |

|

26.

Finally! The steel for the office building arrives. In this photo

I pulled one of my no-no's and accidentally got my shadow in

the picture. The four truckloads were the first round of three

more deliveries that would come over the next two weeks. This

photo was taken on Jan 15, 2009. |

|

27.

Second no-no. Did it again! Or did I? One "tell" is

the date. This photo was taken by Roy. This photo can also indicate

the approximate time. If you know that (1) Roy is facing west

north west, (2) the sun is rising directly behind him, and (3)

the long cast of his shadow you can tell that the sun is just

coming over the horizon so it's very early in the morning. This

is the condition of the site on Jan 21, 2009. |

|

28.

On Jan 21, 2009 you can also see progress of the factory. More

importantly for us, after the hurricane our electrical service

was put on the back burner by Centerpoint as their crews were

tied up repairing downed and damaged power lines around Harris

and Ft. Bend counties. This photo shows that by mid January we

have the poles and hardware in place, however, the service is

still not ready. Throughout this time the general contractor

is working with one single electrical service point between the

buildings. The extension cords are getting too long so generators

are deployed to supplement the lack of electrical services. |

|

29.

A concrete pump truck moves into position. In the background

you can see that the building is coming together. This is on

February 12, 2009 and the second floor is getting ready to be

poured. One thing about this project is that the General Contractor

kept things moving. When we couldn't work on the building, or

he had an excess of manpower he put them to pouring or getting

the site ready for parking lot pours. |

|

30.

Finally, Centerpoint arrives with the the main factory transformer.

These transformers have to be ordered 6-9 months in advance so

when you start such a project you want to determine your anticipated

power usage and get the electrical provider on the line early

and get this one item ordered as early as possible. Another early

stage item is to understand the requirements for the pad, and

for the barriers. Here you can see that we've already set inserts

for the barriers so that we could pour the parking lot. The pipe

barriers would be inserted into the sleeves and cemented in later. |

|

31.

Yours truly standing with the pump truck operator as we pour

black concrete on the second floor. Although warned that the

concrete would crack, and were even taken to another facility

and shown the results, it was decided to go ahead and pour anyway.

The concrete did just as promised and the cracks were just too

much so the second floor was finished with carpet and tile. It

turned out beautiful. |

|

32.

The factory is progressing quick although we would like to have

made it much faster. We were working against a production deadline

as well as a construction loan deadline and regardless of the

affects of the hurricane, we needed to be in and cutting steel

within the next 4 months. |

|

33.

Timed with completing the roof the first phase of building a

foundation for a CNC Machining Center is built. The leave-out

and resulting excavation for this project was larger than my

first home. |

|

34.

Workers in this scene give a better perspective of the depth

of this tiered hole. The worker standing at the bottom represents

where a solid concrete monolith will be poured. This will serve

as the foundation for the new CNC machine. |

|

35.

The form is being set for the first pour. That block will be

isolated by a 3/4" fiber shell and the next layer poured.

Then a third until the foundation is completed by the "apron". |

|

36.

A contract sign painter outlines the unique Thrustmaster logo.

Not such an easy task on a corrugated wall. I had just completed

converting the raster image into a vector file in AutoCAD and

Illustrator. The sign painter used that file to layout his pattern

for painting the logo onto the building. |

|

37.

The Thrustmaster logo is finished. We thought about painting

that logo onto the roof so the next time a satellite passes to

take a photo and replace those on Google (TM) and such sites

the building could be seen from space. As it is you can Google(TM)

the address and see it clearly. Furthermore, we were teasing

the idea of putting photovoltaic cells on the roof so the sign

would have been a waste. |

|

38.

Obviously, in building construction the project is the entire

building, not just one floor. There is no such thing as any single

floor affecting only itself. Likewise, the elevator shaft, AC

ducting, chases for wiring and plumbing, and stairwells are examples

of the kinds of "multiple floor high impact" issues

construction projects face. Our design on this elevator shaft

is to also include the circular stairwell between floors. This

minimizes the amount of space needing to be dedicated to both

since they share the same opening and footprint. (The stairwell

was eventually squared but still went around the elevator shaft.) |

|

39.

Barely down 8 feet and we are seeing water in the clay. Our boring

surveys showed something else that made the steel pipe in the

background necessary for setting the piers. Throughout the area

there were layers of sand and silt that would collapse or sluff

off before we could pour the concrete. In this case the sleeve

would be inserted into the hole before the walls sluffed off.

This allowed re-bar to be inserted without worrying about hitting

the walls. Concrete would then be pumped into the sleeve as it

was withdrawn from the hole allowing that the pressure of the

concrete would push against the looser sand and silt while it

set and prevent the walls from collapsing. |

|

40.

The septic system is being installed. One of the delays encountered

during early planning was that the MUD district was having an

issue with another property owner about getting our sewer and

water lines connected. It was also discovered that the water

line was not capable of delivering the amount of water demanded

by our fire suppression system. Rather than wait any longer we

permitted and installed our own septic, water wells, and fire

pump and hydrants. |

|

41.

Installing one of the 7 new cranes. The largest is a 100T with

a 30T auxilliary used for turning large thrusters. |

|

42.

At first the drilling of the well directly in front of the main

building was considered a crazy idea. The challenge was that

we had to be a certain distance back from FM529 and a certain

distance from our second well. While these are considered private

wells they meet the criteria of a public water source and as

such must be inspected every day with reports going to the city

and county. (A recent test in a Louisiana public water system

showed evidence of an omeba which could cause brain swelling.

Thankfully Thrustmasters water is safe and good to drink from

a 300ft deep aquifer.) The well was surrounded by a picket fence

that matched the landscape using palm trees and a flower bed

that "wanders" along side the main walkway. |

|

43.

The pressure tanks also serve as the location for the chlorine

house and chlorine induction system. To the left of the tank

is one part of the 500T chilled water system that will cool the

factory and office alike. In the event of one half of the system

going down the other half can still cool the office and keep

the factory at a reasonable level to allow the temperature sensitive

machines running. |

|

44.

While it may seem such a small concern something as simple as

a sign indicated the address for electrical services installation

can actually delay a project for days or even weeks. If you are

scheduled to have the service connected, and the sign is not

present, they will not install and that moves you to the bottom

of their list. It can be weeks before they get back to you so

put anything like this, no matter how insignificant it seems,

on your MS Project Planning and make sure it gets done. |

|

45. The 100/30 ton crane travels out the

back to load and unload large thrusters onto trucks. The door

opens to the shape of a T allowing the crane to pass through

without fully exposing the air conditioned factory to the full

onslaught of Texas heat and humidity.

This area out back has been converted to

a test area.

|

|

46.

The entrance to the building boasts a 5000lb NiBrAl prop that

was polished and mounted to a shaft sitting atop two bearings.

The entrance had to be reengineered to hold the additional weight

in a 110mph wind for 2 hours. We estimated that turning only

2 rpm, with the bearings being maintened properly, should have

a life of about 3000 years. |

|

47.

The reception desk was designed between myself, the recepionist

Pat Little, and the owners wife, Corry Bekker. I modeled the

reception desk in AutoCAD and took it to Impressions Millwork in Cypress, TX. Brian

Dumaine, Chief Designer & CEO, took our concept and ran with

it makeing this beautiful piece of funcitonal art. |

|

48.

This concrete well is being set in order to install the suicide

fire pumps to the pond below. There are two pumps feeding a pressure

tank which maintains pressure on the factory and office sprinkler

system. When the pressure drops in the tank the first pump automatically

starts and stabilizes the pressure. If the first pump can not

maintain the pressure, or fails to start over a period of time

the second put starts. |

|

49.

These are called suicide pumps because there is no safety involved.

These pumps run until they die or the fire is out. They are inspected

on a regular basis and the fuel is replaced as needed to keep

the pumps ready for a fire. They have since been enclosed with

a fence to keep the cows out and for additional security. |

|

50.

Signage for the front entrance is developed using AutoCAD to

define the general layout and plan for accessing the sign and

lighting inside. The 3D model (right) gives an idea of how it

would have appeared with the building in the background. 50.

Signage for the front entrance is developed using AutoCAD to

define the general layout and plan for accessing the sign and

lighting inside. The 3D model (right) gives an idea of how it

would have appeared with the building in the background. |

|

51.

The Giddings - Lewis CNC prepares to run its first part. The

two employees stretching the tape were not doing so for any reason

needed by the CNC. They were setting up a fixture in QC to mount

the thruster base for checking once the part was completed. |

|

52.

The test pond, planned to be 35 feet deep, was analyzed with

the companies hydaulic software. In the center is a model of

a thruster. The colored zones show how the pressures would have

progressed throughout various thruster speeds over time. Before

completion we determined that we would also need to build a 15ft

wall along the back of the test pond to prevent the water from

spilling out and requiring refilling with each test. |